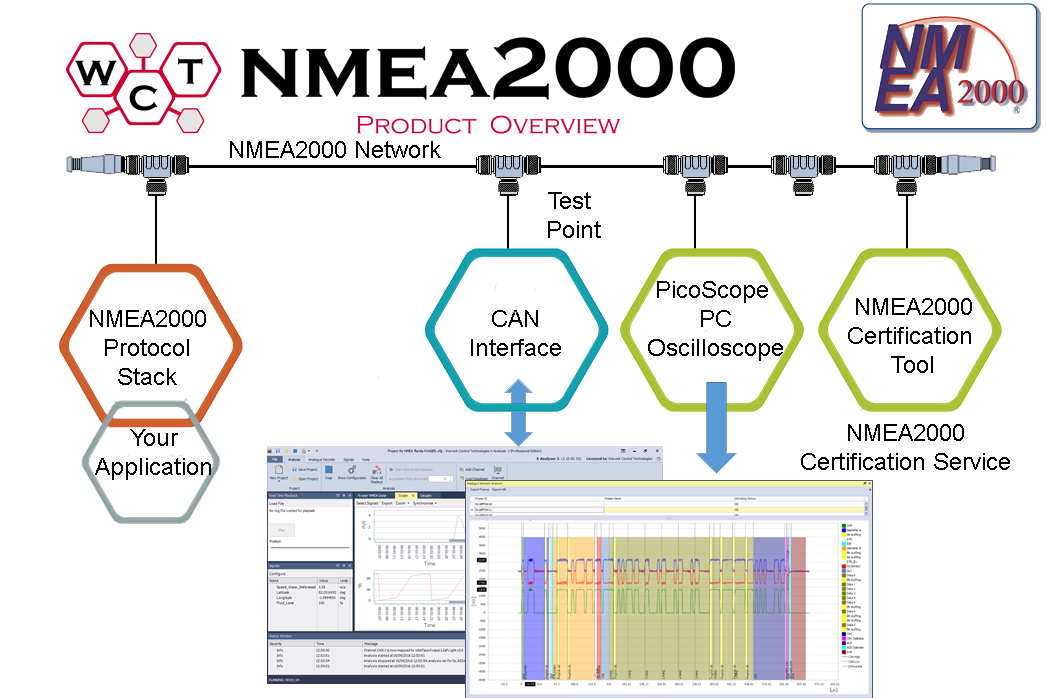

NMEA2000 is a CAN based protocol used in many marine applications.

Warwick Control provides the following NMEA 2000 products and services:

- X-Analyser – a specialised CAN analysis tool allowing the user to look at CAN data-link, electrical/physical and NMEA2000 layers of communication

NMEA2000 Protocol Stack Kit for device manufacturers needing to rapidly develop a NMEA2000 device and pass the NMEA2000 product certification easily.

NMEA 2000 PGN Libraries – Add on C source code libraries for the NMEA2000 Protocol Stack Kit. Includes PGN handling for Battery, Power, Electric Propulsion and Entertainment.

NMEA 2000 CAN Gateway – integrate CAN devices into NMEA 2000 networks

- Marine NMEA2000 CAN Scope Kit – comprising of X-Analyser, hardware and cables to diagnose CAN/NMEA2000 networks.

Marine NMEA2000 CAN Analysis Kit – This kit is ideal for testing and diagnosing NMEA2000 networks.

We can also support you with the following engineering services:

NMEA2000 Pre-Conformance Test

This is recommended for customers needed to check the main software conformance to the NMEA2000 communication requirements and the CAN signalling of a prototype device.

This requires the device to be sent to Warwick Control and the following is carried out:

- Checks are made to ensure that key NMEA2000 services are supported by the device using the X-Analyser tool (e.g. Address Claim, Product Info etc.)

- NMEA Software Tests – Section C3 of the NMEA2000 Specification using the NMEA’s Official Certification Tool

- Check the signal quality of the CAN_H and CAN_L lines

Deliverables are:

- Report on failures and recommendations on what needs to be fixed

Required from the customer:

- Device to be tested

- NMEA Manufacturer Code (if available)

- NMEA Product Code (if available)

- Tx/Rx PGN List

- Part Numbers of the software and hardware

NMEA2000 Full Product Certification

This is recommended for customers that feel their device is ready to go for full product certification with the NMEA. This includes a check of both software and hardware of the device.

This requires the device to be sent to Warwick Control and the following is carried out:

- Checks are made to ensure that key services are supported using X-Analyser (e.g. Address Claim, Product Info etc.)

- NMEA Hardware Tests – Section C2 of the NMEA2000 Specification using the NMEA’s Certification Tool

- NMEA Software Tests – Section C3 of the NMEA2000 Specification using the NMEA’s Certification Tool (AC/DC Isolation, supply voltage variation/interruption etc.)

- Check the signal quality of the CAN_H and CAN_L lines

Deliverables are:

- If it FAILS – Report on failures and recommendations on what needs to be fixed

- If it PASSES – Report on tests which is sent to the NMEA. We will liaise with the NMEA.

Required from the customer:

- Device to be tested

- NMEA Manufacturer Code

- NMEA Product Code

- Tx/Rx PGN List

- Part Numbers of the software and hardware

- LEN

- CAN Component Details

- CAN Bit Timing Details

- Details on any EMC or FCC testing carried out

- Product user documentation

NMEA2000 Design Audit and Troubleshooting

We can help troubleshoot problems on your NMEA2000 device system. This includes aspects like:

A deep look at each of the NMEA2000 devices by investigation of the CAN electrical signals, existence of error frames, bus loading and message timing.

CAN bit timing advice.

Stress testing.

Code reviews under non-disclosure agreement.

Please contact sales@warwickcontrol.com for more information.

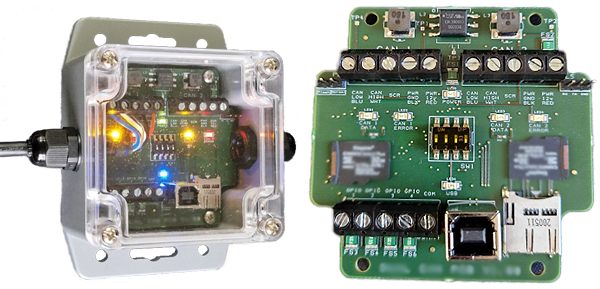

NMEA 2000 CAN Gateway

Integrate CAN devices into NMEA 2000 networks. One side connects to the NMEA 2000 network whilst the other side connects to a CAN bus.

Available as a gateway ECU in IP67 casing or as a bare PCB. Warwick Control will customize the firmware to your requirements.

I/O and Features

- 2 x CAN

- 4 x General Purpose I/O

- Powered 9 to 30v

Applications:

- Integrate Electric Propulsion devices into NMEA 2000 (e.g. battery management, motor)

- CANopen to NMEA 2000

- SAE J1939 to NMEA 2000

Please contact sales@warwickcontrol.com for more information.